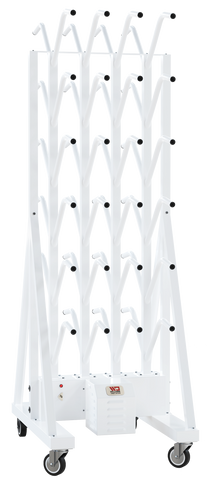

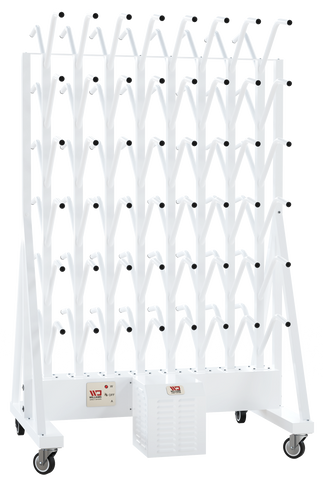

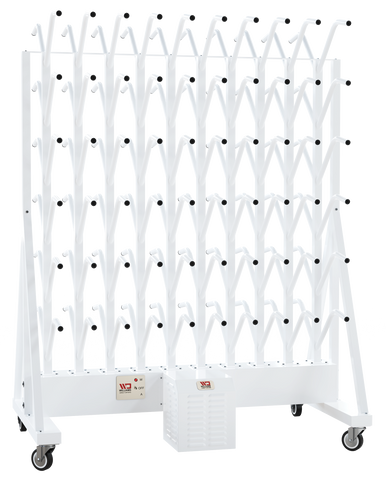

Gear Dryer for Oil & Gas Workwear

INDUSTRIAL GEAR DRYERS FOR OIL & GAS COMPANIES

We Dry Your Wet Gear Fast

At Williams Direct Dryers, we provide top-quality oil & gas gear dryers for those who work in the oil and gas industry. Those working on offshore rigs are virtually certain to end their workdays with gear that is wet, damp and a breeding ground for bacteria and infection. Nothing is better at drying boots, gloves, uniforms and more than the heavy duty dryers found at Williams Direct Dryers. Our oil & gas dryers come in a variety of options, including portable dryers and wall mounted dryers. And no other ambient or forced air dryers on the market can match their performance and durability. The Williams Direct name is highly respected in our industry, and our products are a valued resource for those involved with rugged duty careers. On and offshore oil rigs certainly fit the bill when it comes to rugged duty, and our glove and boot dryers fit the bill when it comes to eliminating bacteria, reducing the chance for infection and keeping gear safe, comfortable and dry. Williams Direct Dryers has been making specialty dryers for various industries since 1989. Since we’ve been at it so long, we’ve become experts at what we do. To learn more about the many benefits of our industrial gear dryers on industrial workwear, see our product gallery or continue reading. When you neglect the care of industrial clothing and equipment, it may not provide workers adequate protection from injuries and illnesses. Therefore, the importance of keeping industrial clothing and equipment dry in the workplace using an oil & gas dryer cannot be overstated. Taking proper care of your industrial gear dryer and personal protective equipment (PPE) is critical in many work industries, such as oil and gas, manufacturing, construction, healthcare, and more. When you correctly care for industrial gear, it adequately protects against chemicals, flying debris, sharp objects, and other hazards.

Benefits of Using Our Industrial Gear Dryer

Extends Life of Gear

When moisture accumulates on industrial gear, both from sweat and the outer environment, it leads to quicker deterioration. Workwear that retains moisture quickly attracts mildew and mold, which, if not addressed, destroys the material. With our dryers here at Williams Direct Dryers, thorough drying is done in as little as two hours, preventing mildew and mold growth. Since our dryers use your choice of warm or ambient air to dry gear, there is no wear-and-tear from tumble drying. Our dryers work in such a way you can use them on the most fragile gear without damaging it. This means you save money due to the expanded shelf life of your equipment.

Why Do Business With Us At Williams Direct Dryers

Since 1989, Williams Direct Dryers has manufactured high-quality specialty dryer products. Our client list speaks to our success, including the US military, NASA, resorts, fire departments around the country, professional sports teams, and more. When you do business with us, we work closely with you to learn your individual needs to find the best dryer for you.

- Our gear dryers are built for durability and long lasting toughness (16 gauge welded construction and powder coated)

- According to an Akron Children's Hospital study, they effectively remove 99.95% percent of bacteria and fungal loads in apparel if used between apparel use

- Designed for continuous duty cycles

- Built in North America using North American parts

- CSA and CE electrical certification

- Five-year warranty on superstructure

- Stops odor in apparel

Prevents Bacteria Growth & Odors

When industrial workwear remains wet, bacteria rapidly grows on it. If this isn’t taken care of, bacteria and mold cause strong odors. A fantastic feature about our industrial workwear dryers is they effectively eliminate 99.95% of bacteria and pathogens. This means that not only will gear smell better but also prevents fungus and bacteria growth.

Prevents Infections & Reduces Sick Days

Since our dryers eliminate 99.95% of bacteria and pathogens, employees are at lesser risk from hazards like staph infections and Athlete’s foot. Ultimately, overall sick days are also reduced, given that workers are less exposed to pathogens that can make them sick.

Built-in Energy Management System

Our industrial workwear dryers all have an energy management system built into them. This ensures that you’re using energy as efficiently as possible, which helps to lower energy costs. Also, you can program our dryers to shut off automatically after a certain amount of time, which prevents wasting energy.

Runs Quietly

While many dryers are pretty loud, that isn’t the case with our units. Our dryers use warm or ambient air to dry clothing and other types of gear, so they are far quieter than any tumble dryer. Since our dryers are quiet, employees and others won’t be distracted by continuous loud noises.

Reduces Downtime That Gear Can Be Used Again

Our dryers work quite fast — typically, it takes only about two hours to dry an item completely. This means using the equipment again quickly by an employee without waiting for many hours or even days before an item is fully dry.

Contact Us Today To Have Your Industrial Gear Dryer Questions Answered

We invite you to learn more about the many gear dryers available to you here at Williams Direct Dryers, including our dryers for the oil and gas industry. As an innovator in our industry, we push the boundaries of what is possible with our state-of-the-art products. So discover for yourself why our dryers are such a valued resource for those in the oil and gas industries. If you’re interested in having your very own industrial workwear dryer, you can reach out to us here! One of our friendly staff members will get back to you and answer any questions you have.